|

GD-Itronix DynaVue Display Technology

The

Ultimate Outdoor-Readable Touch-Screen Display

(June

4, 2007)

by

Technology Editor Geoff Walker -- view PDF version

Don't you

just hate it when some marketing guy labels something as "ultimate"?

Well, I've found something that really should be labeled as "ultimate."

It's General Dynamics (GD) Itronix' brand-new DynaVueTM

outdoor-readable touch-screen display technology. The American Heritage Dictionary

defines "ultimate" as "representing or exhibiting the greatest

possible development or sophistication," and that's an appropriate

description of this new technology. I've been studying and writing about outdoor-readable

screens for quite a while, and there simply isn't anything more that can be

done to a touch-screen-equipped transmissive LCD to make it work any better

outdoors.

Defining

the Problem

To support

my declaration of superiority, this article explains what GD-Itronix has done

and how it works. But before that, to set the stage and describe the scenery,

this article defines the problem, explains how to quantify outdoor readability

and discusses three alternatives for improving outdoor readability.

The real

problem in making any display readable outdoors is reflections. If the light

reflected by the surface of the display is close to or greater than the amount

of light emitted by the display, it can't be read.* In order to read something

on a display, there must be a visible difference between the whitest and blackest

parts of an image on the display. If the surface of the display is reflecting

a lot of light, the difference in the light emitted by the whitest and blackest

parts of the screen is masked ("washed out"), and whatever is on

the screen can't be seen.

The difference

between the whitest white and the blackest black on a display is called the

contrast ratio. The "intrinsic" (datasheet) contrast ratio of a

typical LCD panel is usually at least several hundred to one, and it can be

as high as 1,000:1. In simplified form, intrinsic contrast ratio is calculated

as the amount of light emitted by the brightest white pixel divided by the

amount of light emitted by the darkest black pixel, with the measurement being

made in a dark room. Since an LCD's backlight is always on, what's really

being measured is the ability of the black pixel to block the transmission

of the backlight. It should be fairly obvious that intrinsic contrast ratio

has little or nothing to do with outdoor readability.

Real-World

Contrast Ratio

In the real

world, a user looks at the whole screen outdoors, not just at one pixel in

a dark room. Accordingly, an entirely different method of measuring the contrast

ratio is used in bright-light environments. There isn't a standard term for

this "real world" contrast ratio; it's variously called "high

ambient", "extrinsic" or "effective" contrast ratio.

For the remainder of this article it will be called the latter. Unfortunately,

effective contrast ratio (ECR) numbers are rarely published because they depend

on many hard-to-control factors. As a result, it's usually necessary to estimate

the ECR for any particular display by plugging the display's reflectivity

and backlight brightness into a rule-of-thumb formula. The formula is as follows:

ECR

= 1 + (Emitted_Light / Reflected_Light)

In this

formula, "Emitted_Light" is usually the manufacturer's specification

for the brightness of the backlight in nits. ("Nits" is display-industry

slang for "candela per meter squared", or cd/m2, which

is a technical measure of light intensity.) "Reflected_Light" is

the amount of light reflected by the surface of the display. This is calculated

by multiplying the ambient light in nits by the percentage reflectivity of

the display. Ambient light is normally measured in lux. Sunlight ranges from

approximately 30,000 lux to 100,000 lux; to convert lux to nits, the value

must be divided by Pi (3.14159). The low end of the ambient sunlight range

is therefore usually specified as 10,000 nits (rounding up from 9,549).

Effective

contrast ratio numbers for LCDs are typically in the range of 1:1 to 20:1.

While there is no hard and firm standard, the following table provides a generally

accepted interpretation of ECR values.

|

Effective Contrast

Ratio (ECR) |

LCD

Outdoor Readability

|

| 1-2 |

Unreadable

in sunlight |

| 3-4 |

Adequately

readable in shade; barely readable in sunlight |

| 5-9 |

Adequately

readable in sunlight; looks OK |

| 10 |

Very

readable in sunlight; looks good |

| 15 |

Outstanding

readability; looks great |

| 20 |

Totally

awesome; excellent readability; can't be improved |

For comparison,

the equivalent ECR of the New York Times newspaper in sunlight is around 20:1,

which is about as good as it gets. A typical notebook LCD in 2007 has a 200-nit

backlight and a surface reflectivity of about 2%. Plugging these numbers into

the ECR formula shows that the typical notebook is essentially unreadable

in sunlight, as follows:

ECR

= 1 + (200 / (10,000 x 0.02)) = 1 + (200 / 200) = 2:1

High-Brightness

Backlights

Since the

backlight brightness appears in the ECR formula, it seems reasonable that

increasing the backlight brightness should make the display more readable

outdoors. Typical "high-bright" displays used in industrial applications

have 1,000-nit backlights. Substituting 1,000 for 200 in the numerator of

the formula yields an ECR of 6:1, which is "adequately readable in sunlight".

However,

there are several problems with this approach. First, increasing the backlight

brightness to 1,000 nits isn't appropriate for portable computers. It drastically

increases the power consumption, which reduces battery life and generates

a lot of heat which must be removed with a fan or heatsink. Second, the extra

brightness tends to overpower the dark pixels' ability to block light, which

causes dark colors to appear gray and the image to look washed out. Third,

this approach assumes that the reflectivity of the display surface remains

at 2%, which is usually not the case for any display with a protective cover

or touch screen.

Resistive

Touch Screens

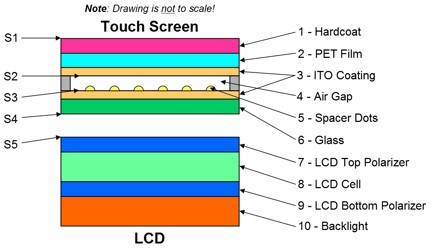

Figure 1 below shows the construction of a typical analog-resistive

touch screen. This type of touch screen is very commonly used in portable

computers. (Note: Numbers in parentheses in the following paragraphs refer

to the layer ID numbers on the right side of each Figure.)

A resistive touch screen consists of solid glass substrate (6) coated with

indium tin oxide (ITO) (3), a transparent conductor. A flexible polyester

(PET) membrane (2) also coated with ITO (3) is suspended above the glass substrate.

Transparent spacer dots (5) keep the two conductive surfaces apart, forming

an air gap (4). A hardcoat (1) makes the surface of the polyester membrane

more resistant to wear. The force of a touch collapses the membrane, causing

contact between the conductive surfaces. Electronics measures the resistance

along the edges in two dimensions and calculates the point of touch.

Figure 1: Construction of a typical

analog-resistive touch screen

Because

of the air gaps, a resistive touch screen has four reflecting surfaces, identified

as S1 through S4 in Figure 1 above. In addition, the LCD surface also reflects

light (S5 in Figure 1). Surfaces S1 and S4 each reflect 4% of the incident

light (normal for PET and glass), while surfaces S2 and S3 each reflect around

5% (higher because of the ITO). Surface S5 reflects about 2%, as previously

described. The total reflectivity is therefore 20%. Plugging 20% into the

ECR formula with a 1,000 nit backlight yields the following result:

ECR

= 1 + (1,000 / (10,000 x 0.20)) = 1 + (1,000 / 2,000) = 1.5

It's clear

that an LCD with an untreated resistive touch screen is unreadable in sunlight,

even with a 1,000-nit backlight!

Resistive

Touch Screen Treatment #1

There are

two alternative treatments that can be applied to resistive touch screens

to reduce their reflectivity. In the first treatment, touch-screen surfaces

S1 through S4 and the LCD surface S5 in Figure 1 are coated with anti-reflective

(AR) material.

AR coatings

are sometimes called "index-matching films" because one of their

functions is to reduce the effect of the difference in index of refraction

between air (1.0) and glass (1.5), PET (1.6) or ITO (2.0). Yet another name

for AR coatings is "quarter-wavelength films." If the thickness

of an AR coating is exactly one-quarter (or an odd multiple of one quarter)

of the wavelength of light, destructive optical interference takes place and

some of the reflections cancel each other out. High-quality AR coatings consist

of multiple layers of different materials, and they're not inexpensive, so

this treatment can multiply the cost of the touch screen by as much as 3X

or 4X.

The best

performance that can be achieved with five AR coatings is a total reflectivity

of around 5% (S1 through S5 = 0.5% + 2.5% + 1% + 0.5% + 0.5%). The primary

constraint is that reducing reflections from ITO on PET film (surface S2)

is particularly difficult because the required flexibility limits the number

of AR material layers that can be applied. While the resulting 5% is a substantial

improvement over the 20% described above for a totally untreated touch screen

& LCD, it's still not good enough, since even with a 500-nit backlight,

the ECR is still only 2:1.

Resistive

Touch Screen Treatment #2

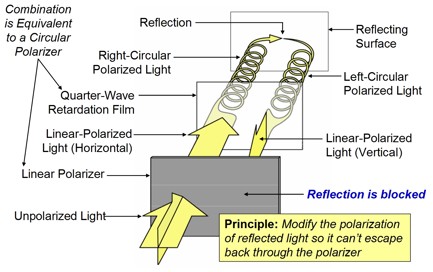

The second

alternative treatment involves the use of a circular polarizer. This requires

a bit of background explanation before proceeding further. Figure 2 below

illustrates how a circular polarizer eliminates reflections.

Figure 2: The use of a circular polarizer

to eliminate reflections from a surface.

(Artwork courtesy of Gunze USA)

In Figure

2 above, unpolarized light goes through a linear polarizer and becomes polarized

in the direction of the polarizeris axis (shown as horizontal in Figure 2).

The light then goes through a quarter-wave retardation film and becomes right-circular

polarized. (A retardation film's name comes from the fact that it "retards"

or delays the phase of light waves sent through it by a quarter-wavelength,

which changes the polarization of the light. The combination of a linear polarizer

and a retardation film creates a circular polarizer.) Circularly polarized

light changes orientation when it bounces off a surface, so the reflected

light on the right side of Figure 2 becomes left-circular polarized. When

the light goes back through the retardation film again, it reverts to linear

polarization, but this time at right angles to the original direction of polarization.

The linear polarizer therefore blocks the reflected light. In Figure 2 the

linear polarizer and retardation film are shown separately for clarity; in

actual practice they are laminated together.

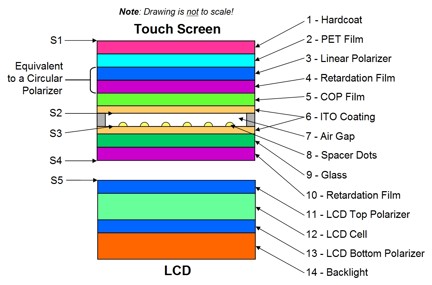

Figure 3:* The application of a circular

polarizer to a resistive touch screen.

Figure 3

above illustrates how a circular polarizer is applied to a resistive touch

screen to reduce reflections. Figure 3 is identical to Figure 1 with the addition

of items (3), (4) and (10), and a change in item (5). The circular polarizer

(items 3 & 4) is identical to the circular polarizer in Figure 2, except

that they are shown as laminated together. Item (5), the touch-screen flexible

membrane, can't be made of PET in a circular polarizer system because PET

introduces some undesirable retardation of its own. Instead, the membrane

must be made of a different, non-retarding material. One of the commonly used

materials is cyclo olefin polymer (COP) film, shown here as an example.

The second

retardation film (item 10 in Figure 3 above) is not involved in reducing reflections.

It is required because of the presence of the circular polarizer. The light

emitted by the LCD (from the backlight) is linearly polarized as a result

of items (11) and (13).* This light would normally be blocked by the circular

polarizer (3 & 4) the same way that reflected light is blocked. The second

retardation film changes the light emitted by the LCD from linearly polarized

to circular polarized so that it can go through the circular polarizer (items

3 & 4) and be seen by the user. Without item (10), all light from the

LCD would be blocked.

The circular

polarizer reduces the reflections from surfaces S2 and S3 to a very low level

(about 0.1% each). However, its effect starts at item 3 and ends at the top

surface of item 10. That means that surfaces S1, S4 and S5 still require expensive

AR coatings. The best performance that can be achieved with this scheme is

therefore a reflectivity of 1.7% (S1 through S5 = 0.5% + 0.1% + 0.1% + 0.5%

+ 0.5%). This is a lot better than 20% but still not quite good enough.

Assuming a backlight brightness of 500 nits, the ECR formula estimates a contrast

ratio of (1 + (500 / 170)) = 3.9, which is still only ibarely readable in

sunlight.

GD-Itronix'

Ultimate Solution: DynaVue

GD-Itronix

has taken two significant steps beyond the structure illustrated in Figure

3. The first step is to increase the backlight brightness moderately to 500

nits. This causes fewer problems than the 1,000 nit backlight described under

"High-Brightness Backlights" above.

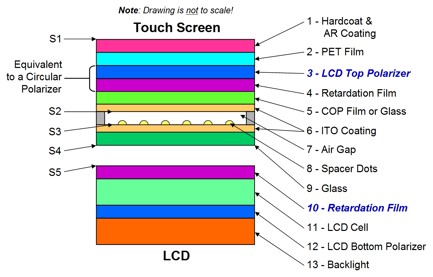

The second

step is to relocate the top polarizer on the LCD (item 11 in Figure 3) and

the second retardation film (item 10 in Figure 3). This new construction is

shown in Figure 4 below, where the relocated LCD top polarizer is item (3)

and the relocated retardation film is item (10).

Figure 4: The construction of GD-Itronixi

DynaVue outdoor-readable touch-screen display.

The second

retardation film (item 10 in Figure 4) is still required because of the circular

polarizer (items 3 & 4), as explained under Figure 3. However, the new

location of the second retardation film means that reflected light from surfaces

S2 through S5 are all blocked by the circular polarizer. This means

that the only surface that requires AR coating in this construction is S1,

which makes it more economical. The performance that results from this construction

is a reflectivity of 0.9% (S1 through S5 = 0.5% + 0.1% + 0.1% + 0.1% + 0.1%).

Finally, this is a good number! Plugging a

500-nit backlight brightness and the 0.9% reflectivity into the ECR formula

yields the following result:

DynaVue

ECR = 1 + (500 / (10,000 x 0.009)) = 1 + (500 / 90) = 6.6:1

This is

well within the "adequately readable in sunlight" range of 5:1 to 9:1 shown

in the ECR table near the beginning of this article.

Just how

good is this? The notebook with the best outdoor readability on the

market today is a semi-rugged Dell notebook without

a touch screen). The Dell has a 500-nit backlight and an AR-coated cover-glass

optically bonded directly onto the LCD that produces a total reflectivity

of 0.5%. The ECR formula estimates the following result for the Dell:

Dell

ATG ECR = 1 (500 / (10,000 x 0.005)) = 11:1

From the

raw numbers, it sounds as though the Dell at 11:1 should be substantially

better than a DynaVue-equipped Itronix product at 6.6:1. However, someone

who has seen the Dell notebook and the new Itronix VR-2 DynaVue-equipped

notebook side-by-side outdoors in direct sunlight told the author that they

are very close in appearance. This is an amazing achievement

for a touch-screen-equipped notebook. Panasonic's best effort, the fully AR-coated,

1000-nit-backlight Toughbook 30 only achieves an estimated effective contrast

ratio of around 3.5:1. (This is based on an analysis of all available product

literature, not on actual measurements or on data from Panasonic.)

The Secret

Sauce

Comparing

Figures 3 and 4, the "secret sauce" clearly is the relocation of

the LCD's top polarizer and the second retardation film. This eliminates almost

all of the reflections from surfaces S4 and S5, which allows the total reflectivity

to be reduced to less than 1%. It also decreases the amount of light lost

in the touch screen, since there are only two polarizers in the system instead

of three. While the secret sauce sounds relatively simple, accomplishing it

is definitely not. It requires very close cooperation between the touch screen manufacturer, the LCD manufacturer and the computer manufacturer to pull off this kind of supply-chain magic.

A Few

Remaining Details

Readers

skilled in the art may notice that there's no anti-glare (AG) coating shown

in the DynaVue construction in Figure 4, only AR (item 1). GD-Itronix has

determined that an AG coating actually decreases DynaVue's performance.

GD-Itronix found that (a) the measured reflectivity of an AG-coated DynaVue

screen is slightly higher, and (b) users testing actual units unanimously

said that the image on an AG-coated screen was less sharp (due to diffusion

of the light emitted by the LCD).

Sharp-eyed

readers may also notice that item (5) in Figure 4, the touch-screen's flexible

membrane, is labeled as "COP Film or Glass." There is no

difference in reflectivity between the two materials, since there are no exposed

surfaces. However, using very thin flexible glass (0.1 mm) instead of COP

film provides a reliability advantage. The two primary causes of touch-screen

failure are (a) cosmetic damage to the top surface, and (b) cracked ITO coating

due to flexing. COP (or PET) film allows the ITO coating to flex at a smaller

radius than glass, which makes the touch-screen lifetime shorter. This is

why the typical specified lifetime of a 4-wire touch screen used with a stylus

is only 100,000 characters.

Readers

skilled in the art may also ask why optical bonding isn't considered in DynaVue's

construction, i.e., bonding the surfaces of items (9) and (10) in Figure 4

to eliminate reflecting surfaces S4 and S5. There are two reasons: first,

once bonded, the touch screen is very difficult to remove. This means that

when a touch screen must be replaced for cosmetic reasons, the LCD must also

be replaced -- which is uneconomical. Second, the performance gain by optically

bonding these two surfaces is only 0.2%, which is a small gain to trade off

against (a) the loss of touch-screen replaceability, and (b) the added cost

of the bonding. Just for the record, the 0.2% reduction in reflectivity would

increase the effective contrast ratio from 6.6:1 to 8.1:1, which is an improvement

of 23%.

Finally,

a few of the major LCD manufacturers such as Samsung are just beginning to

talk about the possibility of "integrated touch screens" in the

near future. What they're really talking about is what GD-Itronix has already

done.* By relocating the top polarizer on the LCD, they are effectively "integrating"

the touch screen into the LCD. All that's missing is optically bonding the

touch screen to the LCD, which as just noted, has some clear disadvantages.

The Bottom

Line

Outdoor

readability is all about contrast, not brightness. The objective is to get

the effective contrast ratio high enough so that the screen can be read comfortably

outdoors. Increasing the effective contrast ratio requires balancing two factors,

the amount of light reflected by the screen (reflectivity) and the amount

of light emitted by the screen (backlight brightness). Managing only one of

the factors won't produce optimum results.

This article

has described four levels of touch-screen treatment, ranging from none to

GD-Itronix' DynaVue, which the author believes is the best on the market today.

The table below summarizes the reflectivity data that has been presented in

this article (in the order it was discussed).

|

Touch-Screen

Treatment |

Surface

S1 |

Surface

S2 |

Surface

S3 |

Surface

S4 |

Surface

S5 |

Total

Reflectivity |

| Untreated |

4% |

5% |

5% |

4% |

2% |

20% |

| 5

AR coatings |

0.5% |

2.5% |

1.0% |

0.5% |

0.5% |

5% |

| Circular

polarizer |

0.5% |

0.1% |

0.1% |

0.5% |

0.5% |

1.7% |

| DynaVue |

0.5% |

0.1% |

0.1% |

0.1% |

0.1% |

0.9% |

This article has

also described a number of real and hypothetical products with and without

touch screens, and with varying combinations of reflectivity and backlight

brightness. These are summarized in the table below (in the order they were

mentioned).

|

Product

Configuration |

Touch

Screen |

Backlight

Brightness |

Total

Reflectivity |

Effective Contrast

Ratio (ECR) |

|

| Standard

notebook |

No |

200 nits |

2% |

2:1 |

|

| High-Bright

industrial display |

No |

1,000 nits |

2% |

6:1 |

|

| High-Bright

industrial display

with

untreated touch screen |

Yes |

1,000 nits |

20% |

1.5:1 |

|

| Notebook

with 5 AR coatings |

Yes |

500 nits |

5% |

2:1 |

|

| Notebook

with circular polarizer |

Yes |

500 nits |

1.7% |

3.9:1 |

|

| GD-Itronix

VR-2 touch-screen

notebook

with DynaVue |

Yes |

500 nits |

0.9% |

6.6:1 |

|

| Dell

notebook |

No |

500 nits |

0.5% |

11:1 |

|

| Panasonic

Toughbook 30 |

Yes |

1,000 nits |

4% |

3.5 |

|

| Optically

bonded DynaVue

(hypothetical,

not available) |

Yes |

500 nits |

0.7% |

8.1:1 |

|

The DynaVue display technology also meets DOD-STD-3009 military standard for cockpit displays for viewability and ambient light ratio.

Geoff Walker, Pen Computing's

Technology Editor, currently heads his own technical marketing consulting firm,

Walker Mobile, LLC.

Based in Silicon Valley, Geoff has particular expertise in touch screens &

digitizers, displays & enhancements, and mobile computers running Windows.

Geoff also writes for SID's Information Display

magazine and the Veritas

et Visus series of display-industry newsletters.* Geoff can be reached at

geoff@walkermobile.com or 1-408-945-1221.

|